Fabrication Capabilities

Waveneys | Our Fabrication Capabilities

Our fabrication workshops are equipped with overhead gantry crane, band saw, guillotine, brake press, drilling, punching, bending, MIG, TIG, gas welding, arc-welding and plastic fusion welding facilities.

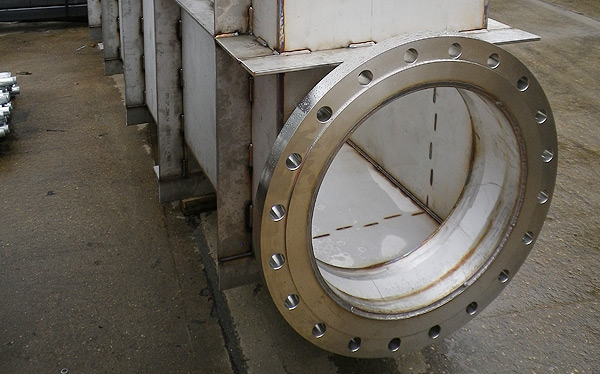

We have the manufacturing experience to enable us to work with a wide range of materials including aluminium, brass, all grades of carbon / stainless steel, engineered plastics and many others. Together with the experienced fabrication staff , this enables us to produce a wide variety of sheet metal work assemblies, structural steel fabrications, prefabricated pipe work and manifolds to meet the client’s needs.

Post manufacture processes can include heat treatment, blast cleaning, galvanising, fusion bonded epoxy coatings and other specialised coatings.

Our dressing capability allows stainless steel fabrications to be finished to a high standard, removing oxidisation marks and re-applying grain to brushed finished items.

Our extensive precision machining facility has the capability to produce machined components for a wide range of industries. These include conventional and the very latest machining technological advancements such as CNC precision turning, milling, horizontal and vertical boring machines. Our staff have the experience and capabilities required to meet a specific need for a single component or a complex multifaceted assembly. We have the flexibility to manufacture a single unit or multiple production runs. CAD/CAM programming can be carried out in-house. Alternatively, we are happy to receive drawings or models from CAD systems for direct input into our CNC machinery.

Automatic bandsaws can cut and mitre all steel sections up to 400mm thick, we also offer gas and plasma cutting of larger steel sections.

Guillotining:

Our guillotine is capable of shearing sheet metal up to 5mm thick with a 3 meter length and 6mm thick sheet metal with a 2 meter length.

Bending:

CNC Brake Press which is capable of bending sheet metal up to 5mm thick with a 3 meter length and up to 6mm thick with a 2 meter length. Our tube bender can bend up to 48mm diameter tube with a wall thickness of 3mm.

Rolling:

We are able to roll sheet metal up to 3mm thick with a width of 1.8 meters and 6mm thick with a width of up to 1 meter.

We offer manual turning, milling, boring and surface grinding. Our manual lathes have a capacity of up to 3.5 metres in length with 3 jaw chucks and 4 jaw chucks capable of holding material up to 800mm. Our two vertical boring machines have a maximum boring capacity of 1.5 metres in height with a 2.8 metre bed travel.

CNC:

We offer 3 axis CNC milling and turning. Our 3 axis CNC mills are ideal for precision work. Our CNC lathes have capacities of up to 1.725 meters in length both having 3 and 4 jaw chucks capable of holding material up to 400mm.

Also in this section…

More >

More >

More >

More >